Technical Sheet

EPOXY FLOOR

Technical Specificatios

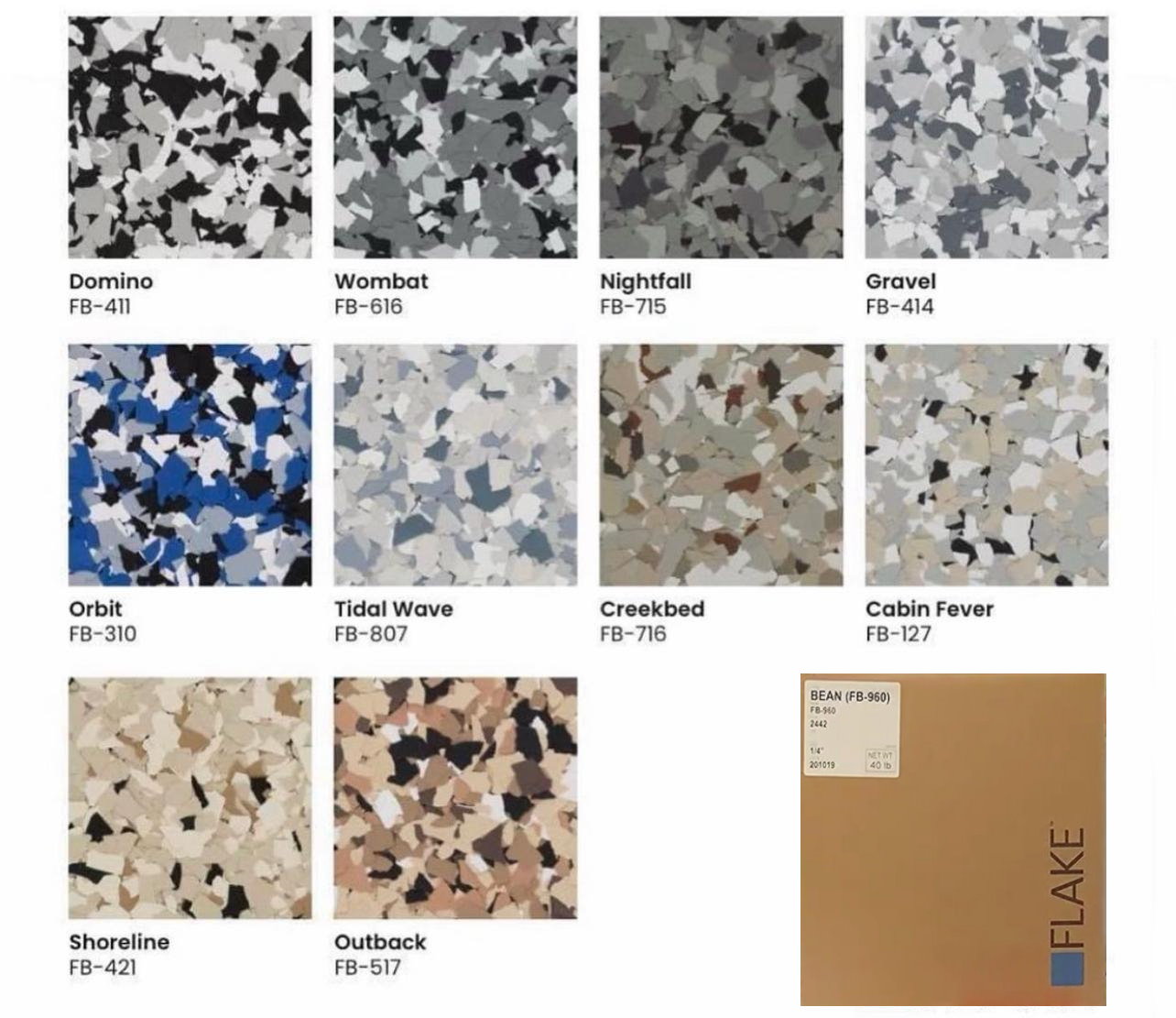

FLAKES

Epoxy Floor with Flakes is a 100% solids, 2 component epoxy. It is a special designed for decorative applications, such as garage floors .....Color flakes are produced from pigments, resin, filler, and additives, are through-colored, random in shape, and available in a wide array of colors to provide unique texture and color to coated surfaces. .....

- For applications over new concrete, it must have at least 28 days of draining in order to achieve its curing and resistance.

- The maximum humidity of the substrate must be less than 4%.

- In order to check humidity, a moisture meter may be used or apply the test of plastic. which consists of placing a piece of plastic on the surface for 24h. If condensation appears under the plastic, moisture or vapor transmission is present.

- Substrates with greater than or equal to 4 % moisture need to use a vapor barrier.

- Pour into a clean, dry container, 2 parts of product A with 1 part of product B, strictly maintaining its proportions.

- We recommend using a low-speed electric drill (300-400. Rpm).

- Mix well to achieve homogeneity, for about 3 minutes.

- To make non-slip coatings or epoxy mortars thicker consult our technical department, to indicate the amount of silica or quartz sand required.

- The product contains substances that if being in contact with the skin and/or inhaled for prolonged periods may cause serious health damage.

- The information contained in this document was given in good faith, based on the experience and knowledge that Servitetop inc. has about the product as long as they have stored, handled and applied it under normal conditions in accordance with the instructions and recommendations of Servitetop inc.

- The information contained herein does not exonerate the user to make the necessary testing of products in places where it will be applied to obtain the best results.

- 2 years in tightly sealed containers, in a dry and cool environment.